Laser Cutting Services: Elevate Your Perforated Metals with Unparalleled Precision

Blog | June 12th, 2024

Laser cutting elevates perforated metals. Discover unmatched precision, intricate designs & faster turnaround times. Upgrade your project today.

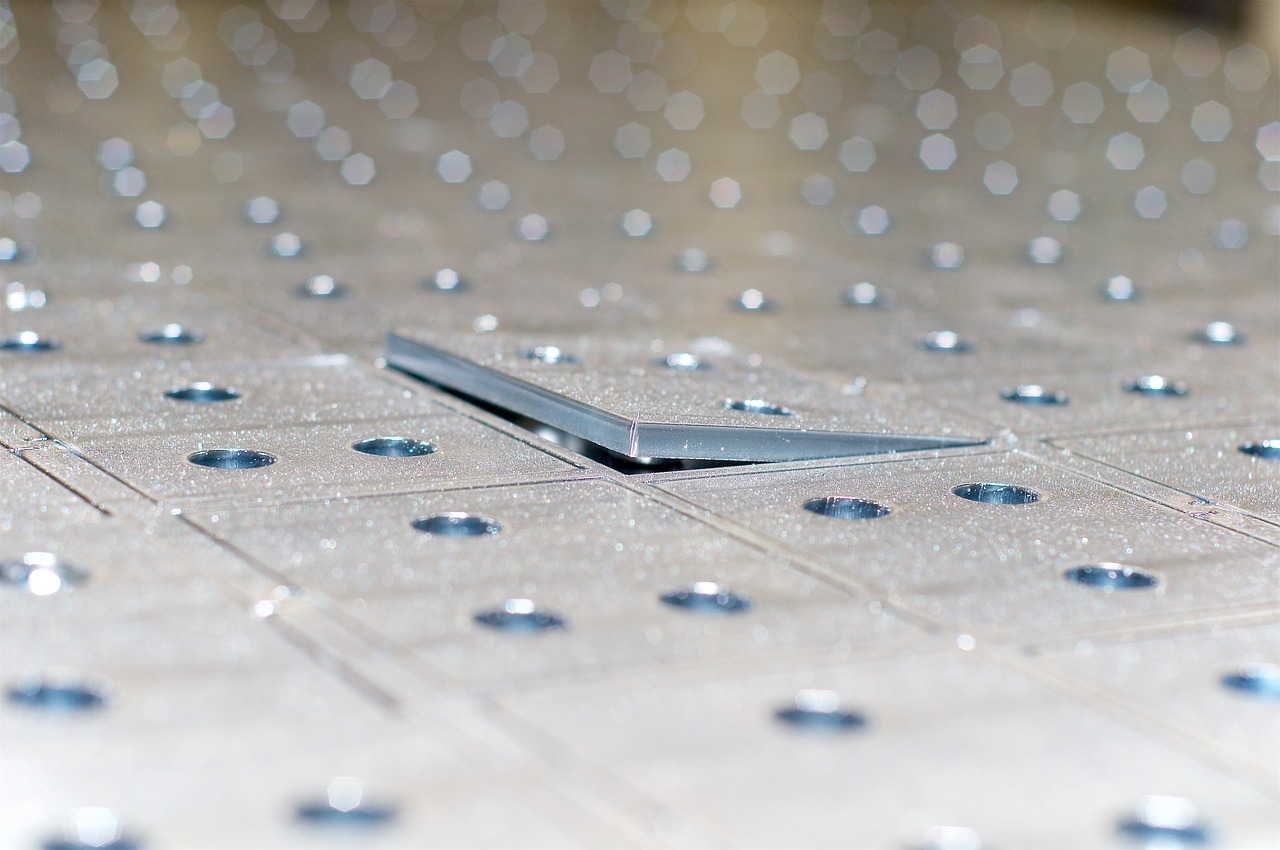

Whether you’re creating intricate architectural features, sleek industrial designs, or eye-catching art pieces, the quality of your perforated metals can make all the difference. That’s where laser cutting services come into play, offering a level of precision that takes your creations to new heights.

Unlike traditional cutting methods like punching or shearing, laser cutting offers unparalleled precision and flexibility, allowing you to unlock the full potential of perforated metals.

The Advantages of Laser Cutting for Perforated Metals

• Unmatched Accuracy: Laser cutting utilizes a focused beam of light to melt and vaporize metal, resulting in clean, precise cuts with minimal kerf (the width of the cut itself). This allows for intricate designs and highly detailed perforations, even with complex patterns.

• Enhanced Flexibility: Laser cutting is not limited by die size, unlike punching. This opens doors to a vast array of hole shapes, sizes, and intricate patterns. You can even incorporate text, logos, or custom designs into your perforated metal for a truly unique touch.

• Reduced Waste: Laser cutting minimizes material waste compared to traditional methods. The precise nature of the cut ensures you get the most out of your material, making it a cost-effective and sustainable solution.

• Superior Edge Quality: Unlike punching or shearing, laser cutting doesn’t create burrs or rough edges. This results in a clean, finished look that requires minimal post-processing.

• Faster Turnaround Times: Laser cutting is a fast and efficient process, allowing for quicker project completion times. This is particularly beneficial for projects with tight deadlines.

Unlocking the Potential of Perforated Metals

With the precision and flexibility offered by laser cutting services, perforated metals can be transformed into a truly versatile design element:

• Architectural Applications: Laser-cut perforated metal panels can be used for facades, cladding, sunscreens, and decorative elements. They can enhance airflow and light control while adding a touch of modern elegance to any building.

• Furniture Design: Create unique and stylish furniture pieces with laser-cut perforated metal for chairs, tables, screens, and more. The perforations can add visual interest while maintaining structural integrity.

• Filtration and Screening: Laser cutting allows for precise control over hole size and distribution, making perforated metals ideal for various filtration and screening applications.

Choosing the Right Laser Cutting Service Provider

To achieve the best results for your perforated metal project, it’s crucial to choose a reputable laser cutting service provider. Here are some key factors to consider:

• Experience: Opt for a provider with experience in cutting perforated metals. They’ll understand the specific requirements and challenges associated with this material.

• Equipment Capabilities: Ensure the provider has laser cutting machines with the power and precision necessary for your project. Consider the thickness and type of metal you’ll be using.

• Quality Control: Choose a provider with a strong commitment to quality control. This ensures your perforated metals meet your exact specifications.

Optimized by NetwizardSEO.com.au