Latest Trends in Metal Hopper Fabrication for Industrial Material Handling Applications

Blog | January 24th, 2025

Metal hopper fabrication is evolving to meet modern industrial needs. McKean’s Sheetmetal Fabricators delivers cutting-edge solutions across Australia.

Metal hopper fabrication is important in industrial material handling, ensuring durability, efficiency, and customisation for various industries. In Australia, McKean’s Sheetmetal Fabricators stays ahead of the curve, offering innovative designs and precision-engineered hoppers tailored to meet the ever-changing demands of manufacturing, mining, and agricultural operations.

What are Metal Hoppers?

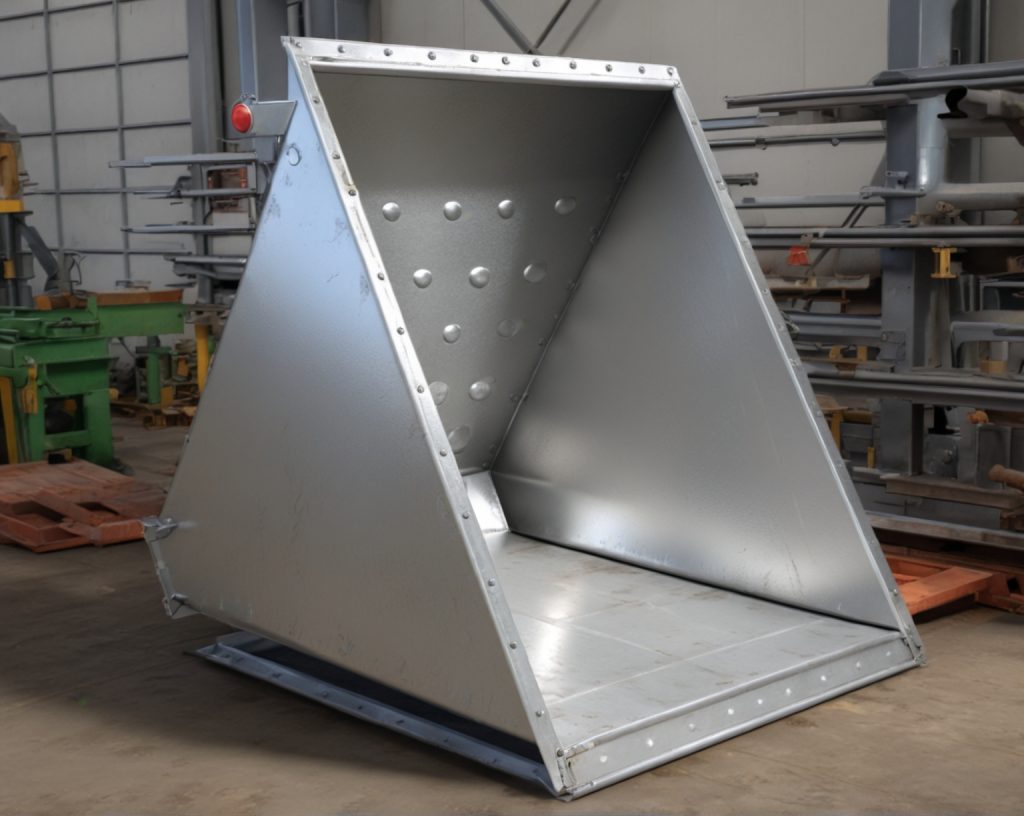

Metal hoppers are specialised containers designed for the storage, handling, and controlled discharge of bulk materials in industrial applications. These metal fabrications are widely used in industries such as mining, agriculture, construction, manufacturing, and waste management to facilitate efficient material transfer and processing.

Some notable characteristics of metal hoppers are:

• Tapered Shape: Hoppers typically have a funnel-like shape with a wider top and a narrower bottom. This design allows materials to flow smoothly under gravity toward the discharge point.

• Material Construction: Hoppers are made from durable metals such as stainless steel, carbon steel, or specialised alloys, chosen for their strength, corrosion resistance, and suitability for the materials being handled.

• Discharge Mechanism: Hoppers often include mechanisms like gates, valves, or augers at the base to regulate material flow. These can be operated manually or through automated systems for precision.

• Capacity and Size: They range from small units for light-duty applications to large-scale hoppers for heavy industrial operations, capable of handling tonnes of material.

Latest Trends in Metal Hopper Fabrication

With advancements in technology and evolving industry demands, the fabrication of metal hoppers has seen significant innovation in recent years. These trends are not only enhancing functionality but also optimising efficiency, durability, and sustainability.

Here are some of the latest trends in metal hopper fabrication for industrial applications.

• Customised Designs: One of the most prominent trends in metal hopper fabrication is the move towards highly customised designs. Industries such as mining, agriculture, construction, and manufacturing require hoppers that are tailored to their specific operational needs. Fabricators are increasingly working closely with clients to design hoppers that match material flow characteristics, required storage capacities, discharge rates and mechanisms, and integration with existing systems like conveyors or feeders.

• Enhanced Material Selection: The choice of materials used in metal hopper fabrication is evolving to meet the demands of harsh industrial environments. Stainless steel, carbon steel, and specialised alloys are commonly used, but there is a growing preference for materials that offer corrosion resistance for industries handling abrasive or corrosive materials, wear resistance for applications like mining and quarrying, where materials can cause significant abrasion and lightweight yet durable alloys to reduce transportation and installation costs.

• Modular and Scalable Fabrication: Modularity is becoming a key focus in hopper design. Modular hoppers are fabricated in sections that can be easily assembled or modified on-site. This approach offers several advantages. First, it allows for easier transportation and installation, especially in remote locations. It also ensures scalability to accommodate future capacity increases. Lastly, it provides cost savings through standardised components.

The fabrication of metal hoppers for industrial material handling applications, which can be done by McKean’s Sheetmetal Fabricators, is undergoing a transformative phase, driven by advancements in technology and a focus on sustainability, efficiency, and safety. Customised designs and innovative materials are helping industries optimise their operations and stay competitive.

Optimized by NetwizardSEO.com.au