McKean’s Sheet Metal Fabrication Solutions for Food Temperature Control

Blog | October 19th, 2023

Maintain food temperature control with McKean’s sheet metal fabrication solutions. Uncover how we ensure the efficient storage of goods. Call (03) 9796 3742.

Maintaining proper temperature control is not just a requirement in the food supply chain, it is also a guarantee of safety, quality, and regulatory compliance. Behind the scenes of this vital process lies sheet metal fabrication, which is a versatile solution that can shape the way perishable goods are stored, transported, and delivered while keeping them at optimal temperatures.

We, at McKean’s Sheetmetal Fabricators, know the essence of optimal food temperature control. Hence, our team offers a wide variety of sheet metal fabrication solutions to businesses that deal with perishable goods.

Connecting Temperature and Food Safety

The perishable nature of food products demands precise temperature control to prevent spoilage, bacterial growth, and contamination. Whether it is fresh produce, dairy, frozen goods, or prepared meals, the food industry relies on maintaining consistent temperatures throughout the supply chain. With the following sheet metal fabrication solutions, the safety and freshness of food products can be guaranteed.

• Insulated Storage Solutions: Sheet metal fabrication plays a vital role in creating insulated storage units like refrigerators and freezers. These custom-fabricated structures ensure that food products remain at the required temperature to retain freshness and quality.

• Custom Enclosures: Sheet metal solutions can also be tailored to specific requirements. Walk-in coolers, cold storage rooms, and blast freezers are all examples of custom enclosures that can accommodate different food products and temperature needs.

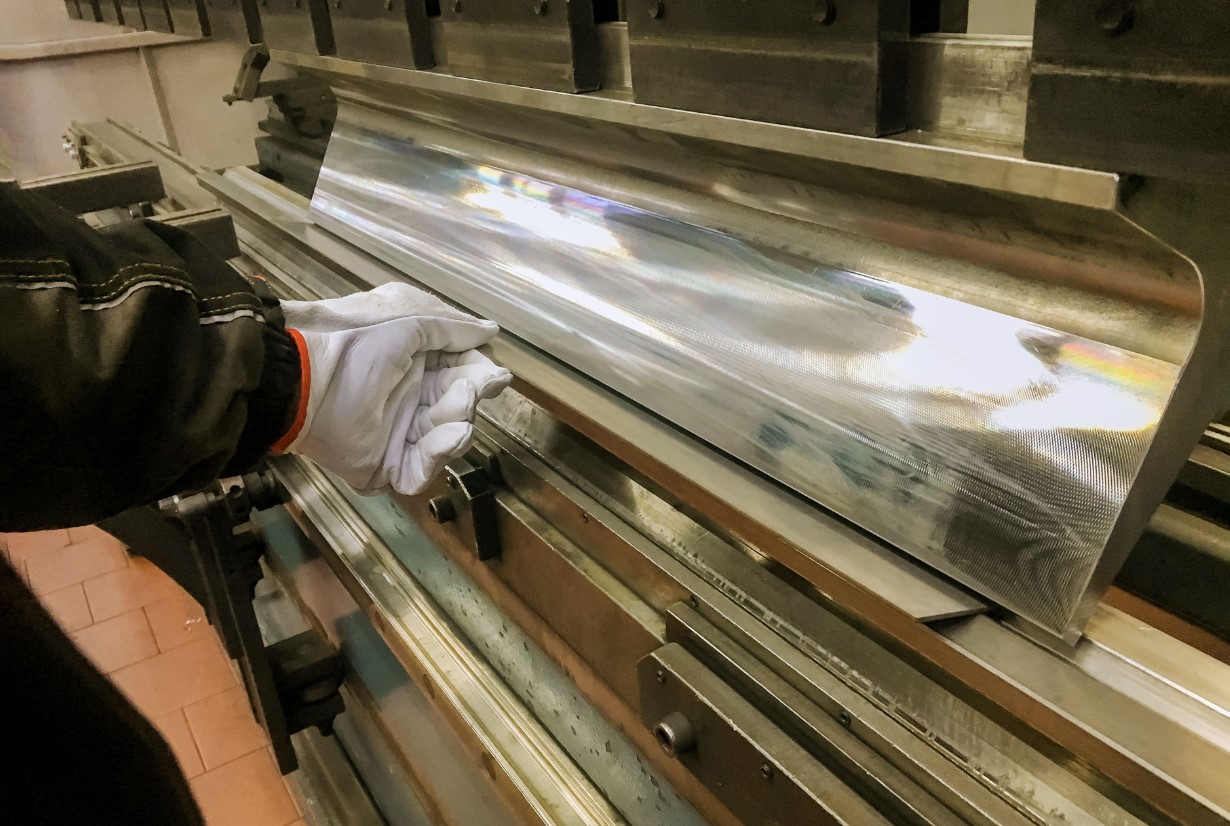

• Precision Engineering: Fabrication techniques like welding and bending enable the creation of precise components that fit seamlessly within temperature control systems. From cooling coils to air distribution systems, sheet metal fabrication ensures the efficiency and effectiveness of food storage and safety solutions.

• Transport Temperature Assurance: The journey from farm to table involves various modes of transportation. Sheet metal fabrication contributes to the construction of temperature-controlled vehicles and their associated components, preserving the integrity of food products during transit.

Food Temperature Control: Main Benefits

In an era of evolving technology and heightened awareness of food safety, sheet metal fabrication continues to innovate to meet the unique challenges of the food industry. Some benefits of sheet metal fabrication solutions for food temperature control are as follows.

• Boosted Energy Efficiency: Fabricated components are designed with energy efficiency in mind, which cuts operational costs while maintaining the desired temperature ranges.

• Ensured Regulatory Compliance: Sheet metal solutions adhere to stringent regulations governing food safety. They provide hygienic surfaces and optimal temperature zones that can prevent bacterial growth, saving food items from spoilage.

• Seamless Integration: Sheet metal fabricated components can likewise seamlessly integrate with existing infrastructure, ensuring that temperature control systems function harmoniously within food processing and storage facilities.

Hiring McKean’s Sheetmetal Fabricators

The synergy between McKean’s Sheetmetal Fabricators’ experts and the food industry ensures that temperature control solutions are not only functional but also aligned with industry best practices. Through our expertise, we can help businesses design systems that precisely meet their temperature control needs. We can also ensure the durability and longevity of components with our quality assurance, reducing upkeep requirements and potential breakdowns.

Optimized by NetwizardSEO.com.au