Roller Plasma Cutting Services: Unlock New Efficiencies in Metalwork

Blog | March 22nd, 2024

Achieve metalwork with enhanced efficiency with roller plasma cutting services by McKean’s Sheetmetal Fabricators. Unlock new potentials in your projects today!

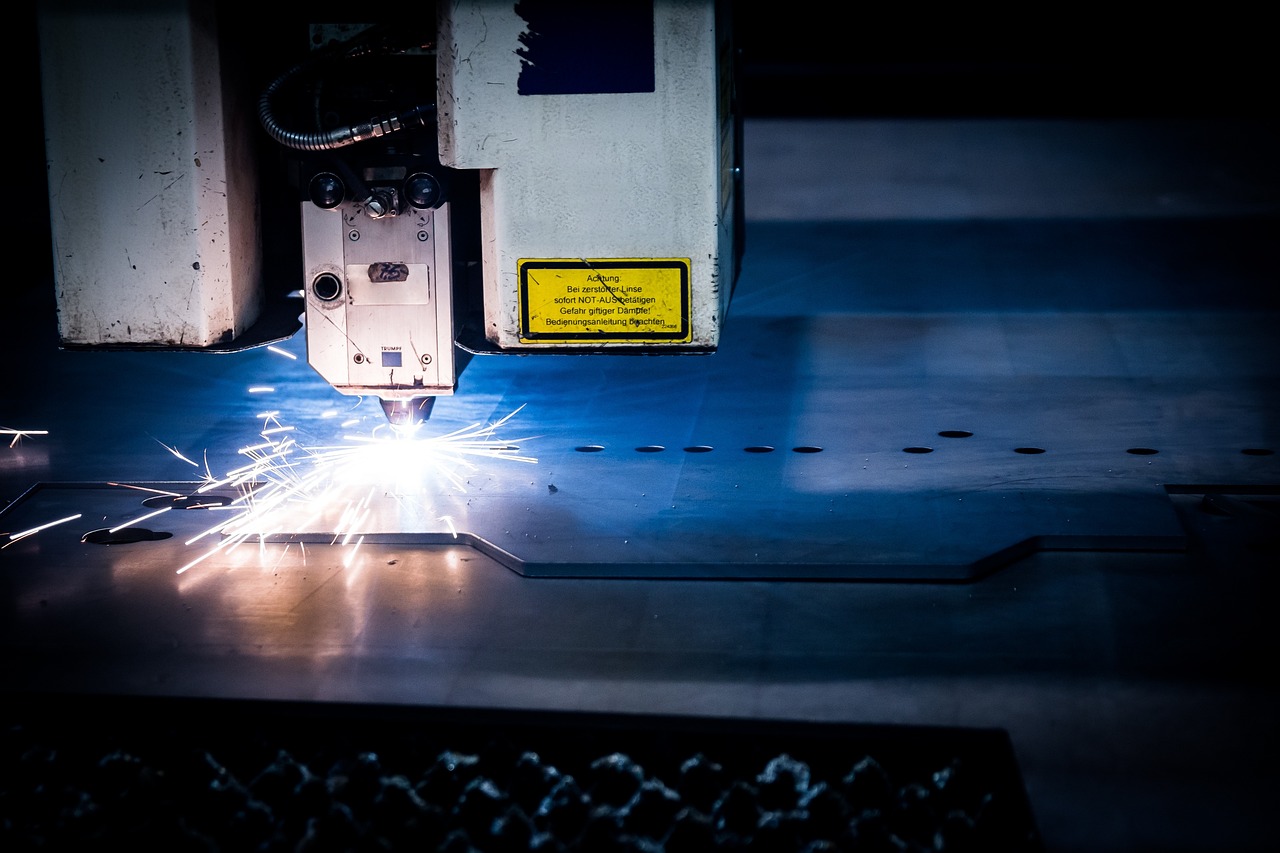

The introduction of roller plasma cutting services in metal fabrication has redefined efficiency and precision in metalwork. These services combine the agility of plasma cutting with the versatility of roller systems, offering a compelling solution for a wide range of industries.

Roller Plasma Cutting in Metalwork

Metal cutting techniques have evolved significantly over the years, transitioning from manual sawing and torching to sophisticated automated systems. Traditional methods may be effective for their time, but they often fall short in terms of precision, speed, and versatility.

The advent of plasma cutting marked a significant leap forward, providing a faster and more precise way to cut through metal. However, it is the integration of roller systems with plasma cutting technology that has unlocked unprecedented levels of efficiency and precision.

Roller plasma cutting is an advanced metal cutting process that maximises a plasma torch mounted on a set of precision-controlled rollers. This combination ensures rapid and accurate cuts across various types of metal sheets and profiles, regardless of their thickness. The roller system guides the plasma torch in a smooth, controlled manner, providing uniform cuts with minimal material wastage.

Benefits of Roller Plasma Cutting

McKean’s Sheetmetal Fabricators offers roller plasma cutting services to industries that require quality parts and components as they can provide the following benefits.

• Unmatched Efficiency: The efficiency of roller plasma cutting services is unrivalled. The system’s ability to make intricate cuts and detailed patterns without compromising speed is a game-changer for industries requiring high precision, such as aerospace, automotive, and construction. The roller system ensures consistent pressure and movement of the plasma torch, which results in clean, burr-free cuts that highly reduce the need for post-processing.

• Enhanced Productivity: Speed is of the essence in any manufacturing or fabrication environment. Roller plasma cutting services dramatically reduce the time required for metal cutting tasks. The fast-moving rollers, combined with the high-speed plasma cutting, mean projects can progress much faster, increasing overall productivity. The speed of these services does not compromise quality as it even enhances it by minimising the potential for human error and material distortion.

• Granted Customisation: The flexibility of roller plasma cutting services extends beyond material versatility. The technology also allows for high levels of customisation, with adjustable settings to cater to different material thicknesses, types, and cutting requirements. These services can be useful in creating intricate designs for architectural metalwork or precise cuts for machine parts, making them a preferred choice for custom projects.

• Ensured Versatility: One more standout feature of roller plasma cutting is its versatility. This technology is not limited to cutting standard steel or aluminium; it can also efficiently process stainless steel, copper, brass, and more. The wide-ranging capability of the process makes it an invaluable tool for workshops and manufacturing plants that work with diverse materials, ensuring they can meet various project requirements with a single, efficient solution.

Partner with Skilled Professionals

Roller plasma cutting services not only elevate the quality and precision of metalwork but also introduce new efficiencies that can transform production timelines and outcomes. If you want to gain the previously stated benefits of roller plasma cutting services, partner with McKean’s Sheetmetal Fabricators today! Unlock new potentials and drive innovation in metalwork with us.

Optimized by NetwizardSEO.com.au